[ad_1]

What number of several types of meeting duties are there? And which must you automate?

Meeting is one of the crucial frequent classes of duties that producers select to automate with robots.

In case you’re trying to automate an meeting activity in your manufacturing line, there are a number of choices you may select from.

A few of these duties are simple to automate with a robotic. They may give fast returns and may have a excessive impression in your manufacturing. Different meeting duties are extra advanced and may have a much less clear impression in your manufacturing.

Let’s take a look at 15 frequent meeting duties. We’ll look at that are simple to automate with a robotic and which might be trickier.

What are the broad sorts of manufacturing duties?

There are dozens of various meeting processes in manufacturing. Many of those processes are attainable to automate with a robotic.

You may consider there being 2 broad sorts of duties in manufacturing:

- Course of duties — These contain taking a workpiece and mechanically altering it so as to add worth to it. Examples of course of duties you may automate are machining, 3D printing, and floor ending.

- Meeting duties — These contain taking already-processed elements and fixing them collectively.

On this article, we’re specializing in the second of those.

The two sorts of meeting activity

You may as well consider there as being 2 classes of meeting duties:

- Everlasting becoming a member of strategies — That is the place the meeting operation is, kind of, non-reversible. Examples embrace welding, brazing, and adhesive bonding.

- Mechanical becoming a member of strategies — That is the place the operation is, kind of, reversible. Examples embrace screwdriving, inserting, and knotting.

You may automate each sorts of meeting duties with a robotic.

15 frequent meeting sorts and duties

Listed here are 15 frequent meeting duties that may wish to automate. Some are simple to automate with a robotic whereas others are barely more durable.

1. Adhesive bonding

Adhesive bonding entails becoming a member of two surfaces along with a chemical agent to create a powerful bond. The most typical instance of that is gluing.

As a easy dishing out activity, it is fairly simple to automate adhesive bonding with a robotic.

2. Bolting

Bolting is among the commonest becoming a member of strategies in manufacturing. It entails screwing a nut and bolt collectively. The 2 major sorts of bolted joints are stress joints and shear joints.

Robotic bolting might be easy (so simple as screwdriving) or extra advanced if the nut is unfixed.

3. Brazing

Brazing is a course of for completely becoming a member of two items of steel collectively. Utilizing a high-temperature flame, you soften a filler steel to fill the be part of between the 2 items.

Robotic brazing is definitely attainable. Like welding, it requires a specialist setup.

4. Cable tying

Cable ties are a fast and easily-reversible technique for becoming a member of two gadgets collectively. They’re generally used to hitch cables and tubes.

The trickiest a part of cable tying with a robotic is inserting the tip initially. One resolution may very well be to make use of an computerized cable tie gun as an finish effector.

5. Clinching

Clinching is a technique for becoming a member of sheet steel with out welding or fasteners. It entails mechanically deforming the steel collectively to type a powerful joint.

Robotic clinching is definitely attainable. Nonetheless, it tends to require giant industrial robots and customized tooling.

6. Crimping

Crimping, like clinching, entails becoming a member of two or extra supplies by deforming them. A standard instance is wire crimping to hitch a wire to a connector.

Crimping finish effectors for robots are usually not but widespread, however there are lots of computerized crimping instruments that you may combine with a robotic.

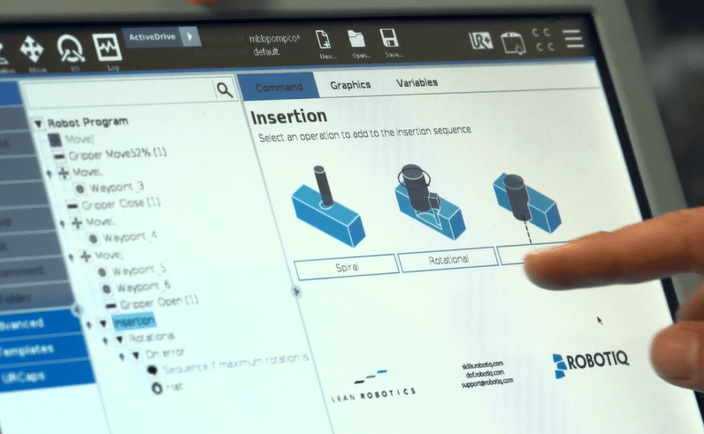

7. Inserting

Inserting is maybe the primary operation you consider when you consider “meeting.” It merely entails pushing one half into one other to create a mechanical match.

It is very simple to automate insertion duties with robots, particularly if you happen to use programming options like Spiral Search.

8. Knotting

Knots are a method to be part of rope and different cords collectively. It is among the best becoming a member of strategies for us people to carry out.

Tying knots with robots is a really advanced activity and is the subject of a lot ongoing analysis.

9. Magnet fastening

Generally, we wish to create an meeting be part of that’s simple to reverse and reattach many instances. For this, magnet fastening is among the commonest becoming a member of strategies.

How simple it’s to automate your specific magnet fastening activity with a robotic is dependent upon the precise activity.

10. Nailing or stapling

Nailing and stapling meeting duties each contain driving stable steel, pin-shaped fasteners into two items of fabric.

Robotic nailing is sort of frequent. The duty requires a particular computerized stapling finish effector.

11. Riveting

What’s essentially the most attention-grabbing meeting activity? It is riveting.

Jokes apart, riveting is a standard and highly-effective mechanical becoming a member of technique. It entails driving a steel rivet into two items of fabric and deforming the rivet to create a powerful connection.

Robotic riveting is feasible with a particular riveting finish effector.

12. Screwdriving

Screwdriving is among the mostly automated meeting duties.

The robotic picks up a screw from an automatic screw feeder. It then drives the screw into the workpiece utilizing a screwdriving finish effector.

With an off-the-shelf Robotic Screwdriving Answer, you may rapidly and simply deploy your personal screwdriving robotic.

13. Soldering

Soldering is utilized in electronics manufacturing to repair parts to circuit boards. A sizzling soldering iron is held to the steel contacts and solder is melted onto them.

Robotic soldering is an more and more frequent type of meeting automation, utilizing a particular soldering device.

14. Staking

Staking entails connecting two parts with an interference match. A steel or plastic “boss” is inserted right into a gap. Then, a excessive drive or ultrasound is utilized to deform the boss, fixing it firmly into the opening.

There are a number of robotic staking options, together with these utilizing ultrasonic staking.

15. Welding

Welding entails making use of warmth, strain, or each, to 2 steel elements. Solder is then utilized to fuse the 2 metals. It differs from brazing in that the warmth is way increased.

Robotic welding is a extremely efficient utility for producers. It gives varied compelling advantages over handbook welding, together with higher consistency, much less post-weld clean-up, and extra environment friendly use of supplies.

Designing for meeting automation: Which to automate

Of all these 15 meeting operations (and any extra you may consider)… which must you automate with a robotic in your facility?

The fundamental rule is to select a activity that’s:

- Easy to automate.

- Excessive impression for your online business.

Say that you simply select robotic screwdriving— a quite common activity to automate. You may then search for examples of different producers who’ve additionally automated this activity with a robotic to find out how they did it.

Which meeting activity will you automate first? Inform us within the feedback beneath or be part of the dialogue on LinkedIn, Twitter, Fb, or the DoF skilled robotics neighborhood.

[ad_2]