[ad_1]

It is a new sequence wanting on the detailed design of varied robots. To begin with we might be wanting on the design of two totally different robots that had been used for the DARPA Subterranean Problem. Each of those robots had been designed for working in advanced subterranean environments, together with Caves, Mines & City environments. Each of those robots offered are from the Carnegie Mellon College Explorer workforce. Whereas I’m writing these posts, this was a workforce effort that required many individuals to achieve success. (If anybody on Workforce Explorer is studying this, thanks for every part, you’re all superior.)

These posts are skipping the system necessities step of the design course of. See right here for extra particulars on defining system necessities.

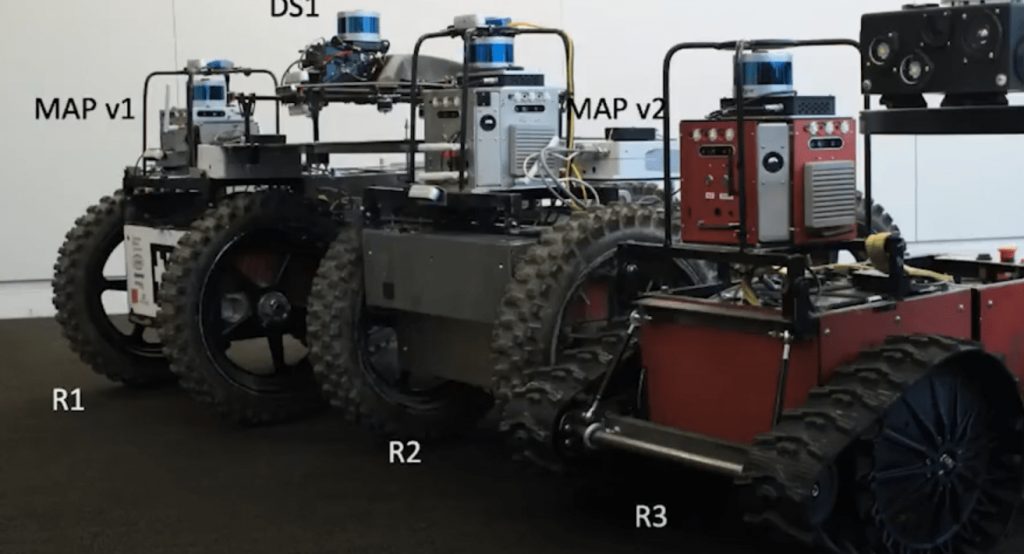

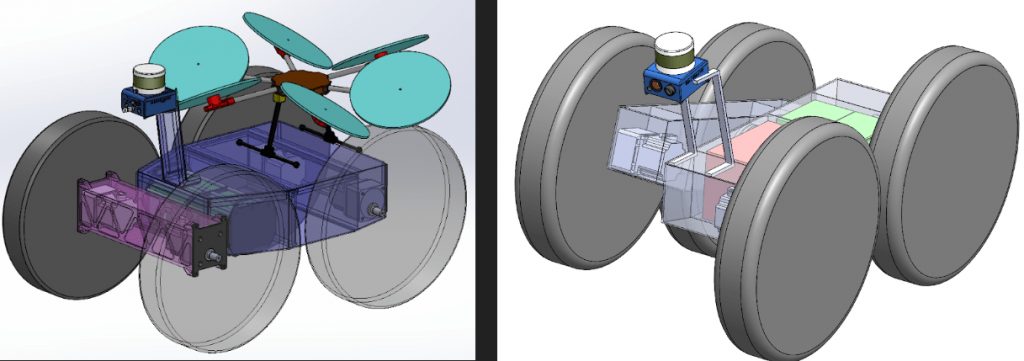

SubT Floor UGV and DS Drone ImageTeam Explorer R1 Floor Robotic and DS Drone [Source]

R3 Floor robotic (UGV)

For the SubT problem three floor autos had been developed all of a similiar design. The bottom robots had been identified with the moniker of R#, the place # is the order we constructed them in. The first distinction between the three variations are

R1 – Static Chassis, so the chassis has minimal floor compliance when driving over obstacles and uneven surfaces. R1 was initially imagined to have a differencing mechanism for compliance, nonetheless attributable to time constraints it was ignored from this primary model. R1 is pictured above.

R2 – Has the differencing mechanism and was designed as initially deliberate.

R3 – Is nearly an identical to R2, however smaller. This robotic was constructed for navigating smaller areas and likewise to have the ability to climb up and down steps. It additionally makes use of totally different motors for the driving the wheels.

DS drone

The unique drone design utilized by Workforce Explorer referred to as their drones D1, D2, and many others.. This let a mix of UGV +Drone go by joint designations corresponding to R2D2. Early on, the workforce switched to a smaller drone design that was known as DS1, DS2, and many others.. The place DS is brief for Drone Small.

The drone design publish are break up into two sections. The primary is concerning the precise drone platform, and the second is concerning the payload that sat on prime of the drone.

Mechanical & wheels

Robotic dimension choice

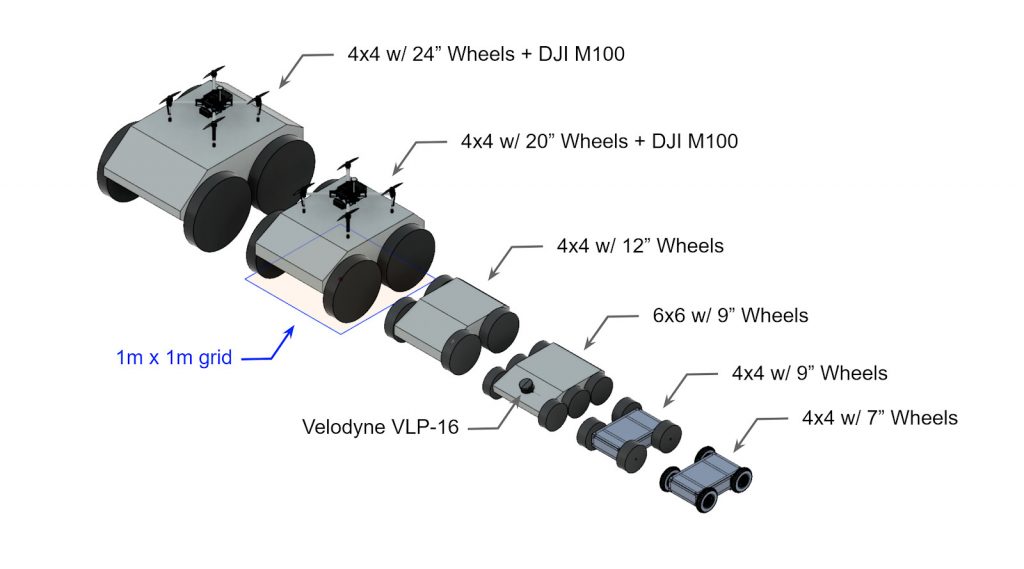

After we’ve the listing of system necessities we begin with the design of the mechanical construction of the robotic. On this case we determined {that a} wheeled robotic can be greatest. We wished to have the biggest wheels attainable to assist climb over obstacles, nonetheless, we additionally wanted to maintain our sensors on the prime of the automobile above the wheels and have the ability to slot in openings 1 x 1 meters. These necessities set the utmost dimension of the robotic in addition to the utmost dimension of the wheels.

The ultimate dimensions of the primary two autos (R1 and R2) had been round (L x W x H) 1.2 x 0.8 x 0.8 meters (3.9 x 2.6 x 2.6 ft). The third smaller automobile was round 1 x 0.6 m (3.2 x 1.9 ft) and designed to suit by 0.7×0.7 m openings.

Steering method

Early on we additionally wanted to find out the tactic of driving. Do we would like wheels or tracks? Will we wish to steer with ackerman steering, rocker-bogie, skid steer, and many others.?

See right here for extra particulars on steering choice.

We selected to make use of a skid steer 4 wheeled drive method for the simplicity of management and the power to show in place (level turns). In the beginning of the competitors we weren’t centered on stair climbing, which could have modified a few of our design selections.

Suspension

The subsequent step was to find out the suspension sort. A suspension is required so that every one 4 of the wheels make contact with the bottom. If the robotic had a static fastened body solely three of the wheels would possibly make contact with the bottom when on uneven surfaces. This would scale back our stability and traction.

We determined early on that we wished a passive suspension for the simplicity of not having energetic parts. With a passive suspension we had been taking a look at totally different sort of physique averaging. We roughly had two selections, front-pivot or side-to-side.

Left picture reveals a front-pivot method. Proper picture reveals a side-to-side differencing technique.

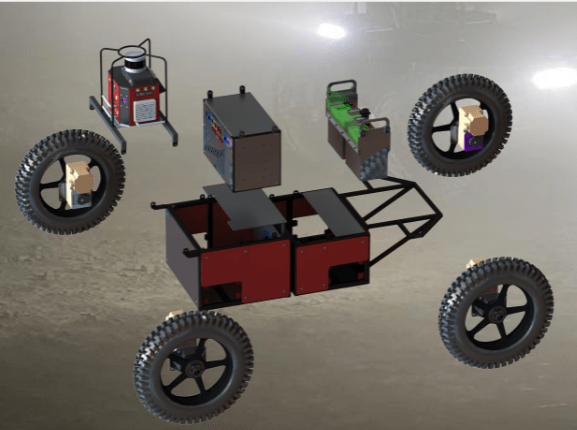

We determined to decide on the front-pivot technique, nonetheless we determined to make the pivot be roughly centered within the automobile. This allowed us to place the entire electronics within the entrance and the batteries within the rear. The front-pivot technique we felt can be higher for climbing up stairs and for climbing over obstacles on stage’ish terrain. Additionally importantly this method made it simpler to hold a drone on the bottom automobile.

Chassis design

At this level we began designing the chassis. This was an necessary step in order that we may estimate the entire weight with the intention to spec the drive-train. Concepts for the chassis had been every part from constructing with 80/20 to constructing an aluminum body and populating it with parts, to a strong welded chassis. We chosen to make use of a welded metal tube chassis for the energy. We would have liked a robotic that might survive something we did to it. This proved to be a smart choice when the robotic crashed or fell over cliffs. The draw back of the metal was elevated mass.

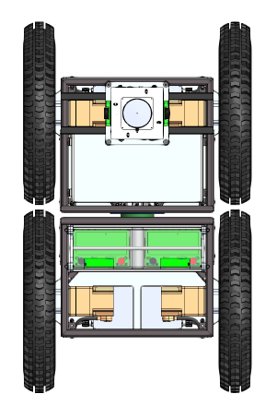

For the pivot we discovered a big crossed curler bearing that we had been in a position to make use of to connect the 2 metal packing containers collectively. The massive bore within the center was helpful for passing wires/cables by for batteries, motors, and many others…

A part of the chassis design was additionally figuring out the place the entire parts ought to mount. Having the batteries (inexperienced packing containers in picture above) within the rear helps us climb obstacles. Different objectives had been to maintain the bottom clearance as excessive as attainable whereas retaining the middle of gravity (CG) as little as attainable. Since these are competing objectives, a part of the design course of was to develop a cheerful medium.

To be able to preserve modularity for service, every wheel module had the motor controller, motor, gear field, and bearing block as a strong unit that could possibly be swapped between robots if there was any points. This additionally allowed many of the wiring to be a part of that block. The one cables that wanted to be related to every of the modules from the robotic had been energy, CAN communications, and the emergency cease line; all of which had been connectorized.

For electronics on R1 and R2 we constructed an electronics field that was separate from the robotic and could possibly be faraway from the robotic as wanted. On R3 we constructed the electronics into the robotic itself. This modular method was very helpful once we needed to do some welding to the chassis post-build for modifications. The draw back of the modular method for electronics was that working within the electronics field was tougher then within the open R3. Additionally the time for fabricating and wiring the R1/R2 electronics packing containers was significantly greater than the open R3 electronics. We additionally had a number of failures throughout testing associated to the connectors from the electronics packing containers.

Wheel design

We debated rather a lot about what sort of wheel to make use of, in the end we used bike wheels as a result of simplicity of acquiring them and mounting them. The wheel diameter we desired additionally lined up very effectively with bike wheels. To be able to get higher traction and skill to climb over obstacles we favored the broader tires.

R1 and R2 had a wheel diameter of 0.55m, R3 had a wheel diameter of 0.38m. This gave R1 and R2 a floor clearance of 0.2m, and R3 a floor clearance of 0.12m.

The wheel hubs ended up being a special story. We discovered strong metallic rims that we needed to machine massive quantities of metallic out of with the intention to steadiness the energy and the burden.

The R1 and R2 robots had been round 180kg (400lb)*, the wheels had been for a automobile considerably heavier. As such we put a small quantity of stress within the wheels to maintain them from falling off, nonetheless we tried to maintain the stress low to extend the bottom compliance of the wheels. This technique added a really small quantity of compliance, we tried eradicating among the rubber from the sidewalls, however was not in a position to get a cheerful medium between limiting the wheel deforming throughout level turns and rising floor compliance.

We had been additionally involved how the bike tires would do when level turning and if we might rip the wheels from the edges. To counter this we put in a beadlock system into every of the wheels. The beadlock was a curved section put in in a number of locations to sandwich the tire to the rim. We by no means had a wheel separate from the rim, so our method positively labored, nonetheless it was a ache to put in.

*R3 was round 90 kg (200 lbs). We tried utilizing totally different wheels and tracks to get R3 to climb stairs effectively. Nonetheless that story is for an additional publish…

The black rims had been strong metallic that we machined the wedges into with the intention to light-weight them. The three metallic posts in these wedges are the beadlock tensioning bolts. You too can see the fortress nut and pin that holds the wheel to the axle. This picture is from R2, you may see the hole between the entrance and rear sections of the robotic the place the pivot is.

Drive-train choice

Now that we had a mass estimate and system necessities for velocity and impediment clearance we are able to begin to spec the drive-train. The opposite piece of data that we wanted and needed to focus on with {the electrical} workforce was the voltage of the battery. Completely different bus voltages vastly impacts the motors out there for a given velocity and torque. We selected a 51.2v nominal bus voltage. This offered an issue because it was very laborious to search out the velocity/torques we wished at that voltage. We ended up choosing a 400W 1/2HP motor+gearbox from Oriental Motors with a parallel 100:1 gearbox that permits us to drive at a most velocity of two.5m/s.

The half numbers of the motors and gearbox on R1 and R2 had been BLVM640N-GFS + GFS6G100FR.

The half numbers of the motors and gearbox on the smaller R3 had been Maxon EC 90 Flat + GP81A.

Subsequent steps

Now that we all know the mechanics of the robotic we are able to begin constructing it. Within the subsequent publish we are going to begin wanting on the electronics and motor controls. Whereas the character of the weblog makes it appear that this design is a serial course of, in actuality a lot of issues are taking place in parallel. Whereas the mechanical workforce is designing the chassis, {the electrical} workforce is discovering {the electrical} parts wanted to ensure that the mechanical individual to know what wants mounted.

It is usually necessary to work with {the electrical} workforce to determine wire routing whereas the chassis is being developed.

Observe of the editor: This publish has been merged from the posts “Arms On Floor Robotic & Drone Design Sequence” and “Mechanical & Wheels – Arms On Floor Robotic Design“.

Robots for Roboticists

David Kohanbash is a Robotics Engineer in Pittsburgh, PA in america. He loves constructing, taking part in and dealing with Robots.

Robots for Roboticists

David Kohanbash is a Robotics Engineer in Pittsburgh, PA in america. He loves constructing, taking part in and dealing with Robots.

[ad_2]