[ad_1]

Steel recycler EMR says it’s taking the subsequent step in its efforts to create a sustainable, round provide chain for uncommon earth magnets.

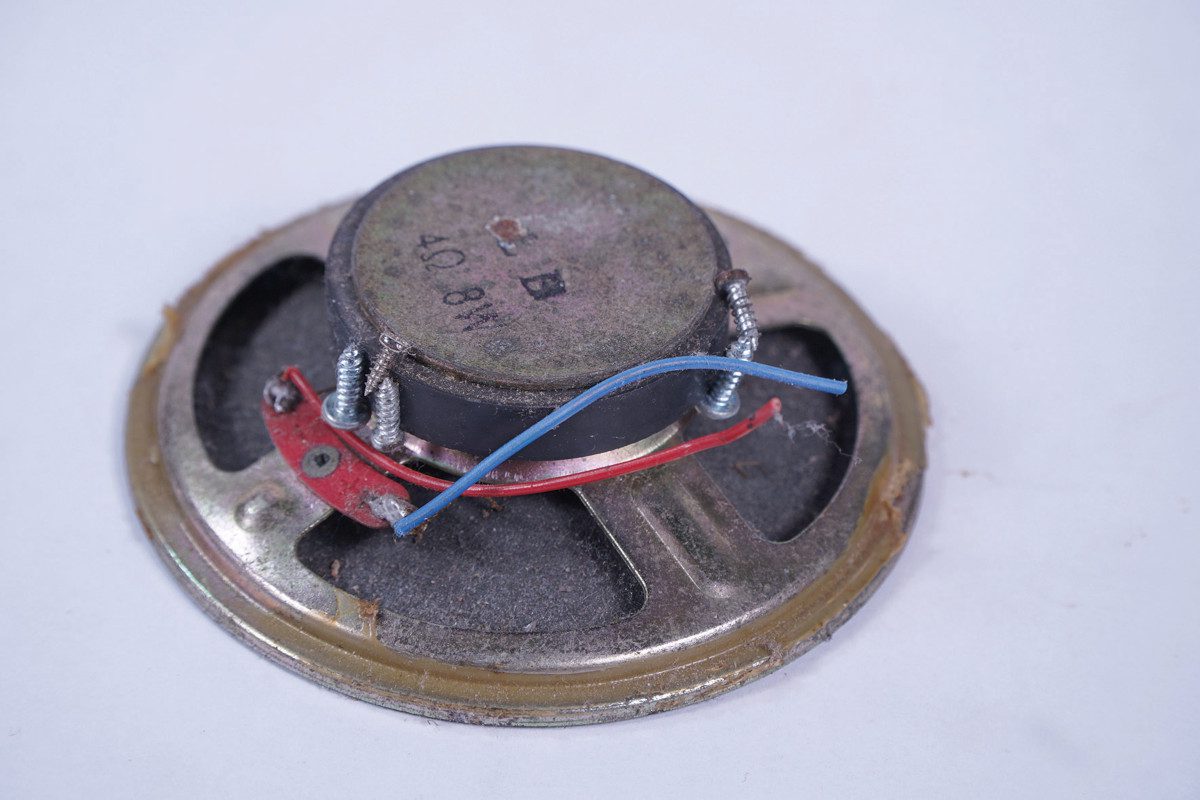

Highly effective neodymium (NdFeB) magnets are a necessary materials in a variety of recent applied sciences, from digital motors and audio audio system to the electrical drive items (EDUs) that energy the most recent electrical automobiles. Extracting the uncooked supplies for NdFeB magnets from the bottom is each carbon intensive and has a damaging impression on biodiversity.

The Safe Vital Uncommon Earth Magnets for the UK (SCREAM) challenge brings collectively a consortium that features EMR, Jaguar Land Rover, GKN Automotive, Mkango Uncommon Earths UK Ltd, HyProMag, Bowers & Wilkins and the College of Birmingham.

EMR is investing £383,000 within the three-year challenge to create a proof of idea. This can be match-funded by the UK authorities through UK Analysis and Innovation (UKRI).

Along with enabling EMR to analyse liberation and processing time, and to determine probably the most environment friendly sources of NdFeB magnets amongst recycled supplies, SCREAM will even assist perceive the longer term market potential of recycled NdFeB magnets, with a view to creating a totally industrial round provide chain sooner or later.

EMR’s associate GKN Automotive Innovation Centre will re-engineer a cutting-edge 800v manufacturing emachine and construct it with specified recycled magnets created by the consortium. As well as, GKN Automotive will check the brand new motor and magnet efficiency to confirm their efficiency and functionality relative to virgin materials and the unique machine.

SCREAM builds on an earlier profitable challenge referred to as REAP (Uncommon-Earth Extraction from Audio merchandise) challenge and utilises Hydrogen Processing of Magnet Scrap (HPMS) expertise developed by HyProMag.

EMR says it can provide high-quality, recycled NdFeB magnets from its waste stream, utilizing processes together with state-of-the-art robotic separation expertise to extract materials from TV audio system, washing machines and end-of-life automobiles. This precious materials would historically have been processed with ferrous metals and misplaced to the availability chain. The SCREAM challenge highlights how EMR is utilizing innovation and new expertise to additional enhance the sustainability of the metallic recycling business.

Dr Joseph Eke, Engineering Analysis and Improvement Supervisor at EMR, stated: “SCREAM is the subsequent thrilling chapter in EMR’s efforts to create a sustainable and round provide chain for rare-earth magnets. That is precious materials which has beforehand been misplaced throughout the recycling course of, however, due to the innovation and insights we now have developed in recent times, we’re now nearer than ever to making sure NdFeB magnets are recycled, processed and re-used for the subsequent technology of purposes.

“Whether or not its mining battle areas such because the Democratic Republic of Congo (DRC) – for cobalt – or politically delicate locations akin to Russia – for nickel – many rare-earth supplies are present in components of the world the place the UK doesn’t have management over their supply. As electrical automobiles are rolled out in larger numbers, the quantity of NdFeB magnets out there within the waste stream will enhance considerably, so it’s now a race towards time to make sure that the business is ready to recuperate this materials effectively and sustainably.

“By working along with the remainder of the SCREAM consortium, EMR is making certain that, sooner or later, there’s a secure and sustainable supply for these supplies that producers and shoppers can depend on.”

[ad_2]