[ad_1]

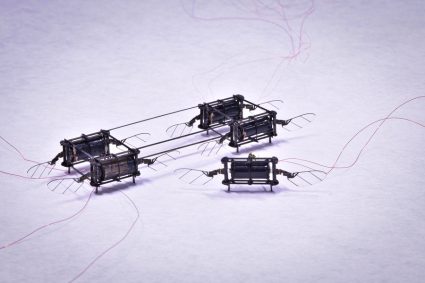

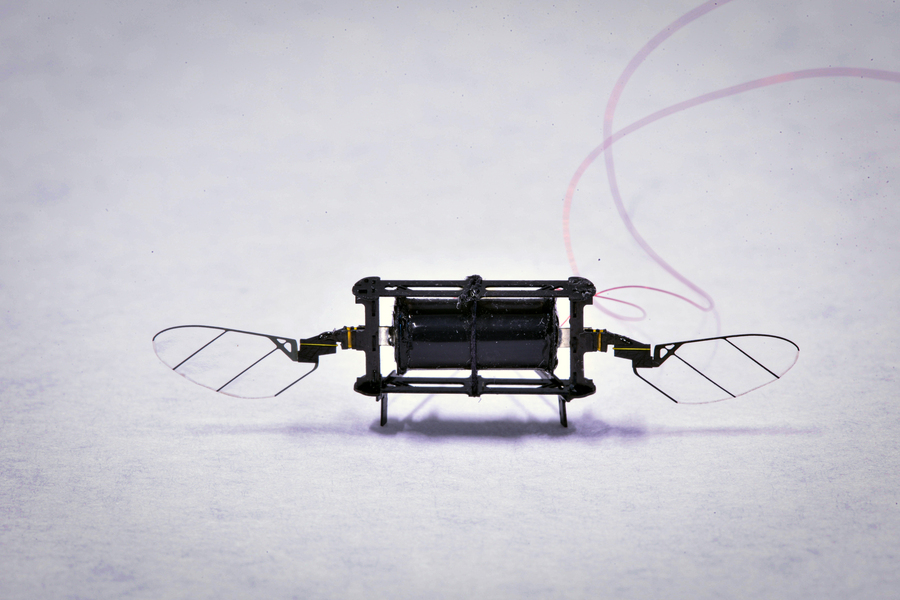

MIT researchers have pioneered a brand new fabrication method that permits them to supply low-voltage, power-dense, excessive endurance comfortable actuators for an aerial microrobot. Credit: Courtesy of the researchers

By Adam Zewe | MIT Information Workplace

With regards to robots, larger isn’t at all times higher. Sometime, a swarm of insect-sized robots may pollinate a subject of crops or seek for survivors amid the rubble of a collapsed constructing.

MIT researchers have demonstrated diminutive drones that may zip round with bug-like agility and resilience, which might finally carry out these duties. The comfortable actuators that propel these microrobots are very sturdy, however they require a lot larger voltages than similarly-sized inflexible actuators. The featherweight robots can’t carry the required energy electronics that will enable them fly on their very own.

Now, these researchers have pioneered a fabrication method that permits them to construct comfortable actuators that function with 75 p.c decrease voltage than present variations whereas carrying 80 p.c extra payload. These comfortable actuators are like synthetic muscle tissues that quickly flap the robotic’s wings.

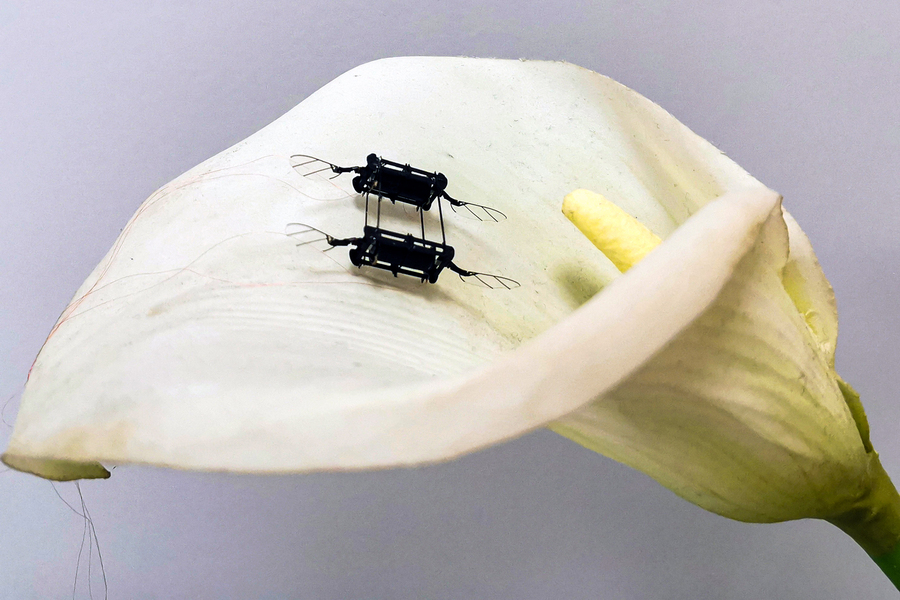

The substitute muscle tissues vastly enhance the robotic’s payload and permit it to attain best-in-class hovering efficiency. Picture: Kevin Chen

This new fabrication method produces synthetic muscle tissues with fewer defects, which dramatically extends the lifespan of the elements and will increase the robotic’s efficiency and payload.

“This opens up quite a lot of alternative sooner or later for us to transition to placing energy electronics on the microrobot. Folks are likely to assume that comfortable robots should not as succesful as inflexible robots. We display that this robotic, weighing lower than a gram, flies for the longest time with the smallest error throughout a hovering flight. The take-home message is that comfortable robots can exceed the efficiency of inflexible robots,” says Kevin Chen, who’s the D. Reid Weedon, Jr. ’41 assistant professor within the Division of Electrical Engineering and Laptop Science, the pinnacle of the Mushy and Micro Robotics Laboratory within the Analysis Laboratory of Electronics (RLE), and the senior creator of the paper.

Chen’s coauthors embody Zhijian Ren and Suhan Kim, co-lead authors and EECS graduate college students; Xiang Ji, a analysis scientist in EECS; Weikun Zhu, a chemical engineering graduate pupil; Farnaz Niroui, an assistant professor in EECS; and Jing Kong, a professor in EECS and principal investigator in RLE. The analysis has been accepted for publication in Superior Supplies and is included within the jounal’s Rising Stars sequence, which acknowledges excellent works from early-career researchers.

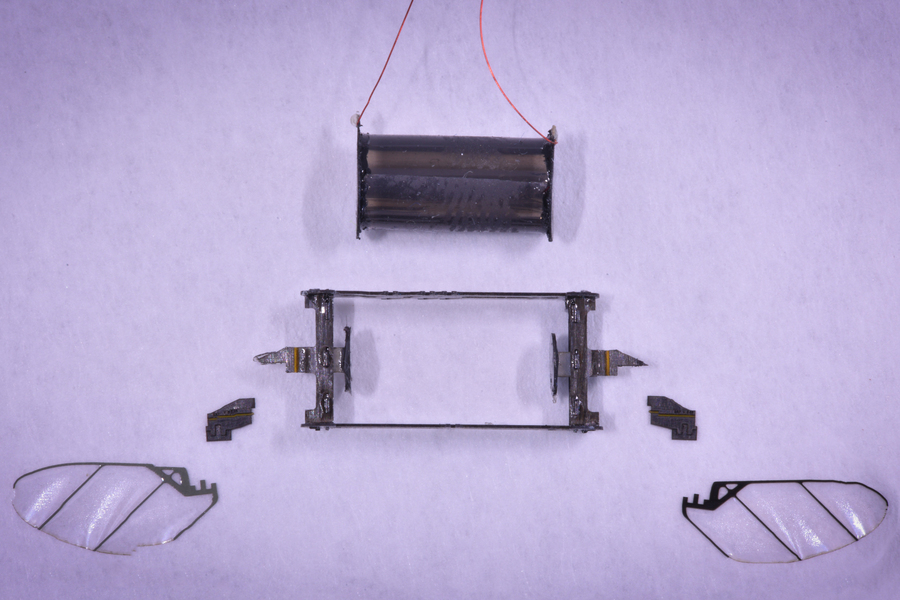

Making muscle tissues

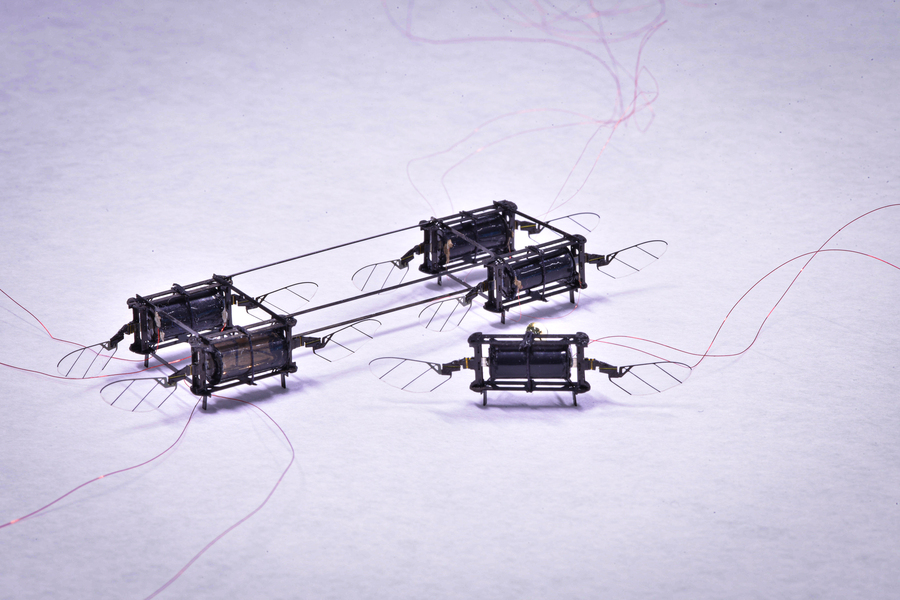

The oblong microrobot, which weighs lower than one-fourth of a penny, has 4 units of wings which might be every pushed by a comfortable actuator. These muscle-like actuators are constructed from layers of elastomer which might be sandwiched between two very skinny electrodes after which rolled right into a squishy cylinder. When voltage is utilized to the actuator, the electrodes squeeze the elastomer, and that mechanical pressure is used to flap the wing.

The oblong microrobot, which weighs lower than one-fourth of a penny, has 4 units of wings which might be every pushed by a comfortable actuator. Credit: Courtesy of the researchers

The extra floor space the actuator has, the much less voltage is required. So, Chen and his group construct these synthetic muscle tissues by alternating between as many ultrathin layers of elastomer and electrode as they will. As elastomer layers get thinner, they turn into extra unstable.

For the primary time, the researchers had been in a position to create an actuator with 20 layers, every of which is 10 micrometers in thickness (concerning the diameter of a crimson blood cell). However they needed to reinvent elements of the fabrication course of to get there.

One main roadblock got here from the spin coating course of. Throughout spin coating, an elastomer is poured onto a flat floor and quickly rotated, and the centrifugal power pulls the movie outward to make it thinner.

“On this course of, air comes again into the elastomer and creates quite a lot of microscopic air bubbles. The diameter of those air bubbles is barely 1 micrometer, so beforehand we simply kind of ignored them. However while you get thinner and thinner layers, the impact of the air bubbles turns into stronger and stronger. That’s historically why individuals haven’t been in a position to make these very skinny layers,” Chen explains.

He and his collaborators discovered that in the event that they carry out a vacuuming course of instantly after spin coating, whereas the elastomer was nonetheless moist, it removes the air bubbles. Then, they bake the elastomer to dry it.

Eradicating these defects will increase the ability output of the actuator by greater than 300 p.c and considerably improves its lifespan, Chen says.

The researchers additionally optimized the skinny electrodes, that are composed of carbon nanotubes, super-strong rolls of carbon which might be about 1/50,000 the diameter of human hair. Increased concentrations of carbon nanotubes improve the actuator’s energy output and cut back voltage, however dense layers additionally comprise extra defects.

As an illustration, the carbon nanotubes have sharp ends and may pierce the elastomer, which causes the gadget to brief out, Chen explains. After a lot trial and error, the researchers discovered the optimum focus.

One other downside comes from the curing stage — as extra layers are added, the actuator takes longer and longer to dry.

“The primary time I requested my pupil to make a multilayer actuator, as soon as he obtained to 12 layers, he needed to wait two days for it to remedy. That’s completely not sustainable, particularly if you wish to scale as much as extra layers,” Chen says.

They discovered that baking every layer for a couple of minutes instantly after the carbon nanotubes are transferred to the elastomer cuts down the curing time as extra layers are added.

Greatest-in-class efficiency

After utilizing this method to create a 20-layer synthetic muscle, they examined it towards their earlier six-layer model and state-of-the-art, inflexible actuators.

Throughout liftoff experiments, the 20-layer actuator, which requires lower than 500 volts to function, exerted sufficient energy to offer the robotic a lift-to-weight ratio of three.7 to 1, so it might carry objects which might be practically thrice its weight.

“We display that this robotic, weighing lower than a gram, flies for the longest time with the smallest error throughout a hovering flight,” says Kevin Chen. Credit: Courtesy of the researchers

In addition they demonstrated a 20-second hovering flight, which Chen says is the longest ever recorded by a sub-gram robotic. Their hovering robotic held its place extra stably than any of the others. The 20-layer actuator was nonetheless working easily after being pushed for greater than 2 million cycles, far outpacing the lifespan of different actuators.

“Two years in the past, we created probably the most power-dense actuator and it might barely fly. We began to marvel, can comfortable robots ever compete with inflexible robots? We noticed one defect after one other, so we saved working and we solved one fabrication downside after one other, and now the comfortable actuator’s efficiency is catching up. They’re even a bit of bit higher than the state-of-the-art inflexible ones. And there are nonetheless a lot of fabrication processes in materials science that we don’t perceive. So, I’m very excited to proceed to cut back actuation voltage,” he says.

Chen appears ahead to collaborating with Niroui to construct actuators in a clear room at MIT.nano and leverage nanofabrication methods. Now, his group is restricted to how skinny they will make the layers because of mud within the air and a most spin coating velocity. Working in a clear room eliminates this downside and would enable them to make use of strategies, akin to physician blading, which might be extra exact than spin coating.

Whereas Chen is thrilled about producing 10-micrometer actuator layers, his hope is to cut back the thickness to just one micrometer, which might open the door to many functions for these insect-sized robots.

This work is supported, partially, by the MIT Analysis Laboratory of Electronics and a Mathworks Graduate Fellowship.

tags: c-Analysis-Innovation

MIT Information

[ad_2]