[ad_1]

Do you need to use a robotic for palletizing? Nice! Simply do not fall into the lure of creating these frequent errors.

The choice of whether or not it’s best to spend money on robotic palletizing could be a robust one. In case you’ve already made this choice, you may assume that your work is finished.

However, there are a number of extra selections you may should make earlier than you may have an operational palletizing robotic. Many of those selections relate to the robotic deployment.

Folks usually make errors throughout this early stage.

Listed here are 9 frequent errors individuals make with robotic palletizing:

1. Selecting the flawed pallet or dimension

A quite common concern with palletizing is selecting the flawed pallet itself. There are numerous forms of pallet together with wooden, plastic, and steel. Some could also be unsuitable on your particular palletizing activity.

Equally, there’s a vary of pallet sizes that you would use with totally different structural properties.

Make it possible for your pallets match the necessities of your activity and are supported by your robotic answer. The Palletizing Resolution, for instance, can deal with pallets of widths and depths between 300-1219 mm and heights of a minimal of fifty mm.

2. Choosing a system with inadequate peak

Many robotic palletizing options in the marketplace can solely deal with shorter pallet heights. This makes them unsuitable when you stack your pallets larger.

Do not make the error of forgetting in regards to the pallet peak if you find yourself choosing your robotic answer. Additionally, think about when you may need to improve the peak of your pallets sooner or later.

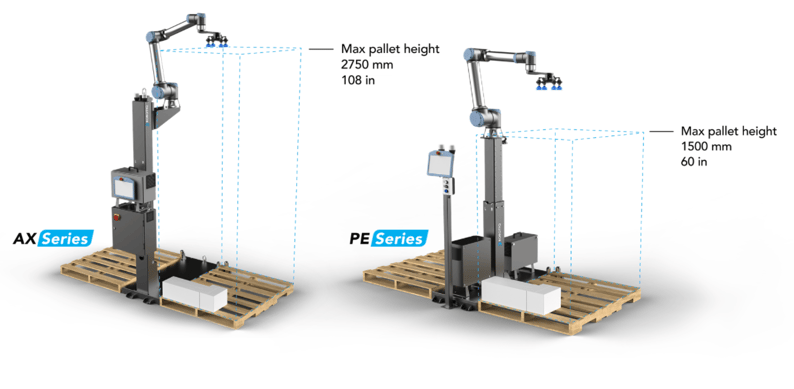

The AX Collection Palletizing Resolution helps pallets as much as 2.75 m and the PE Collection Resolution helps pallets as much as 1.5 m.

3. Forgetting the pre and publish processes

Deploying a robotic palletizing system entails extra than simply the palletizing itself. Your activity could produce other pre-processes and post-processes.

Examples of pre-processes embody labeling the packing containers, studying QR codes from monitoring labels, and sorting objects earlier than the palletizing.

Examples of post-processes embody wrapping the pallet in shrinkwrap, performing an inspection, or labeling your entire stacked, shrinkwrapped pallet.

Customers of The Palletizing Resolution usually discover that the palletizing activity itself is the best a part of the robotic deployment. The pre-processes and post-processes are the place they encounter essentially the most challenges.

4. Overlooking the programming step

It is easy to neglect about programming if you find yourself taking a look at totally different palletizing options on-line. You watch a video or learn a knowledge sheet and also you assume “This answer seems to be prefer it might swimsuit my wants.”

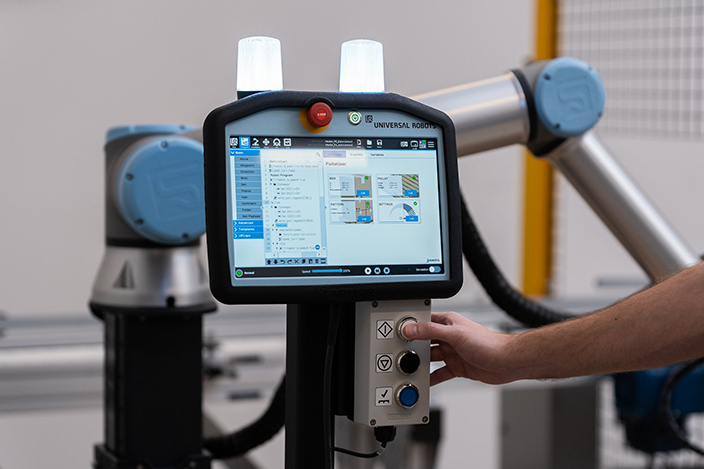

The accessible programming choices can both make your robotic answer extraordinarily straightforward to make use of or extraordinarily advanced. You normally do not see this step in movies.

The perfect robotic palletizing options are really easy to program, you want hardly any coaching to make use of them. Even in case you have no expertise with robotics, you will get the answer up and working in only a few hours. Different options require intensive robotic expertise and coaching.

5. Underestimating the deployment work

You’ll be able to deploy some robotic palletizing options in a matter of hours or days. Different options take loads longer and require vital robotics expertise and ability.

Do not make the error of underestimating how a lot work a robotic deployment will take for you and your staff. It is normally higher to overestimate the deployment than underestimate it. You’ll be able to then be pleasantly shocked when you’ll be able to deploy the robotic extra simply than you thought.

Even higher, perform some research to precisely perceive what the deployment will contain. You’ll be able to see a robotic deployment in motion in our free palletizing course.

6. Not involving the staff upfront

Presumably the largest mistake that some corporations make round robotic deployment is just not getting their staff concerned. They add the robotic to the road out of the blue and the staff reacts badly.

Whenever you contain your staff from the beginning, they are going to be a lot happier in regards to the robotic. They’ll additionally present insights and expertise that may make the deployment run extra easily.

Your staff members have most likely been doing handbook palletizing for a very long time. They’ve distinctive views on the duty that may show you how to get essentially the most out of your palletizing robotic.

7. Ignoring overhangs and different points

A standard mistake with handbook palletizing is overhangs. That is when among the higher layers fall out of alignment and cling over the sting of the pallet. This destabilizes the pallet and might trigger merchandise to fall throughout transit.

With robotic palletizing, maintain an eye fixed out for any concern that you’d additionally need to keep away from with handbook palletizing. Robots are extra constant than people so there may be much less threat of points like overhangs, however they will nonetheless occur when you’re not cautious throughout your deployment.

8. Not utilizing the help you may have accessible

You need not do all the things by yourself.

If you have not deployed a palletizing robotic earlier than, you may really feel like you need to be taught all the things your self. However there may be a whole lot of help accessible which you could benefit from. The DoF robotics group is a good place to go for assist from an entire group of robotic customers.

In case you’re utilizing The Palletizing Resolution, it’s also possible to name us at Robotiq for assist. That is accessible whether or not you may have purchased your answer from an integrator, distributor, or direct from us.

9. Not seeing the answer working upfront

You’ll be able to keep away from most of the frequent errors by simply seeing your palletizing answer in motion upfront. Ideally, you also needs to get the chance to work together with the answer and check out programming it for your self.

That is the one most essential step that many individuals point out after they selected to make use of a Robotiq answer. Whenever you see your answer working, it is a lot simpler to anticipate potential errors that you just may make.

On the very least, watch a video of the palletizing answer in motion. Yow will discover some movies and an interactive palletizing configurator on our product web page.

What errors have you ever made with palletizing previously? Inform us within the feedback under or be a part of the dialogue on LinkedIn, Twitter, Fb, or the DoF skilled robotics group.

[ad_2]